Services

About Our Products

ANKITA ENGINEERING has grow in to one of the leading & trustable Manufacturers of tablet Tooling’s, Pharma machineries, Equipments & Spare parts. Today ANKITA ENGINEERING is one Of the most innovation companies in the pharmaceuticals Industry to face new and innovationchallenge.

ANKITA ENGINEERING is one of the reliable manufacturers and suppliers of tablet punches & dies, pharma machineries, Equipments & spare parts for pharmaceutical companies.

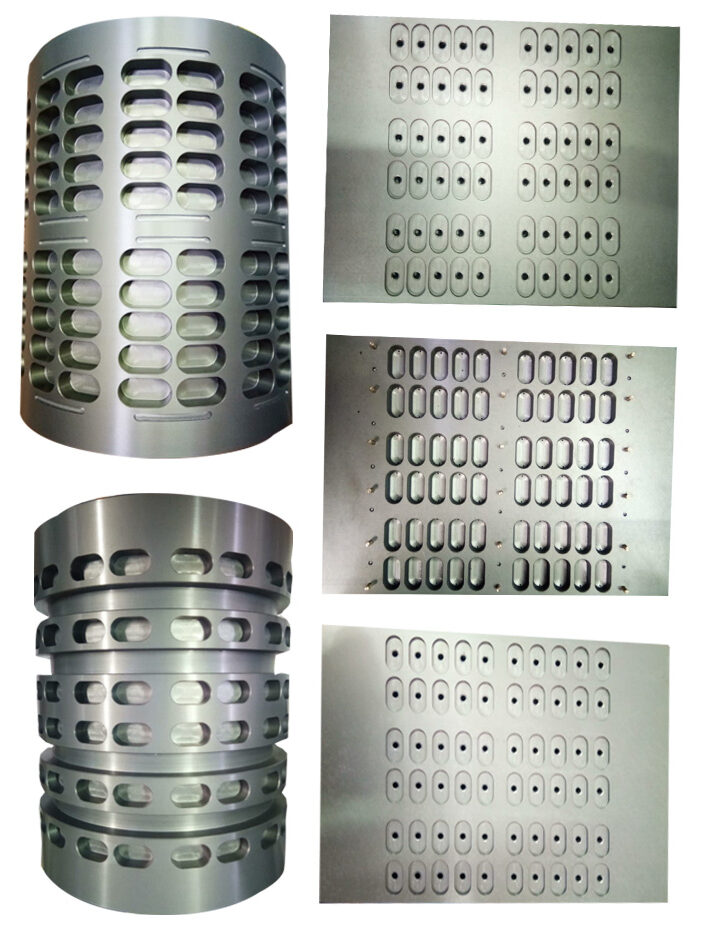

Blister Packing Machine Change Parts

Ankita engineering is into manufacturing of Blister & Alu Alu Change Parts for all Blister & Alu Alu packaging machines. We have team of highly qualified professionals working in state of the art manufacturing facility with latest CNC machines and software applications. We ensure that products we offer are flawless and adhere to set industry norms. We deliver high quality product in minimum time with competitive price.

Our Product Range Includes:

► Blister Forming Roller

► Counter Sealing Roller

► Feeding Channel

► Guide Track

► Punching Tool

► Embossing Tool

► Main Gear

► Bowl Dish

► Bowl Insert

► Indexing Guide Roller

► Perforation Tool

► Printing Drum

► Pressure Sealing Roller With Rotary Connector

► Pin Hole Detector

Blister Change Parts

Blister change parts refer to the components and accessories used in pharmaceutical packaging machines to facilitate the production of different blister pack formats. Blister packaging is a widely adopted method in the pharmaceutical industry for the secure and convenient packaging of tablets, capsules, and other solid dosage forms. The versatility of blister packaging machines allows for the customization of blister packs, and blister change parts play a crucial role in achieving this flexibility.

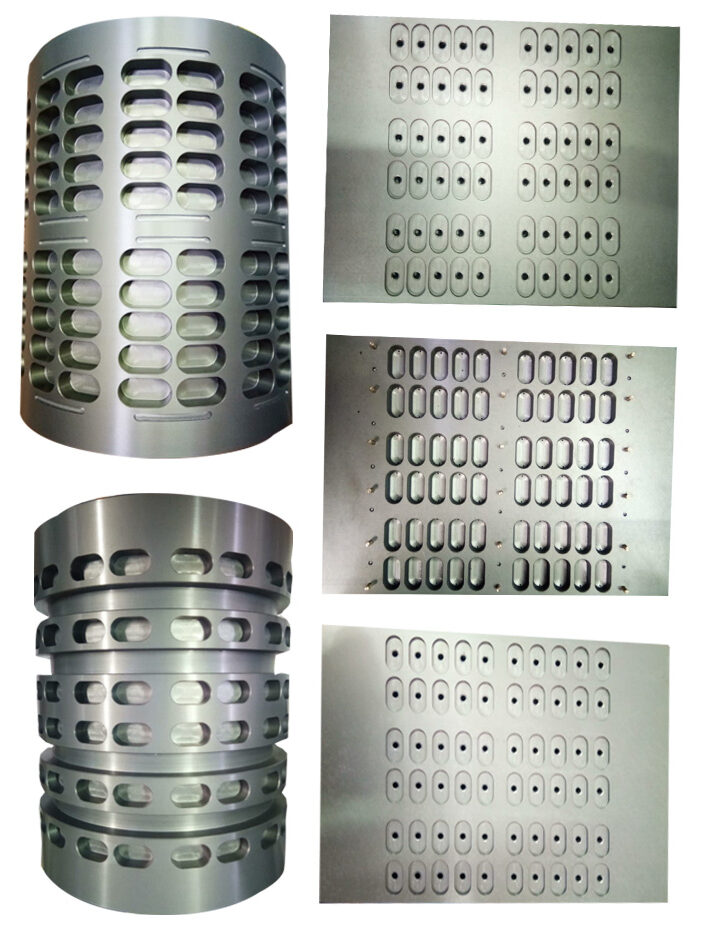

Strip packing Machine Change Parts

We manufacture change parts for strip Packing Machine for all Leading Brand & make. We offer change parts from 02 Tracks To 12 Tracks. Change parts consist of Feeding and Sealing Parts designed specifically to suit the particular product. Each and every set of Change Parts is subjected to complete satifactroy trials (including vacuum leak test) at our works before dispatch.

The Strip Packing Machine offered by us is used for the quality packaging in pharmaceutical industry. The machine is used for packing capsules, tablets, Soft Geletin Capsules and pills. The machine is designed as per industrial standards and are available in different output speeds.

Fluid Bed Dryer Bags

We are one of the distinguished manufactures and suppliers of a Fluid Bed Dryer Bags. FBD Bags (Fluid Bed Dryer Bags) is manufactured using optimum quality raw material, which is sourced from renowned vendors of the nation.

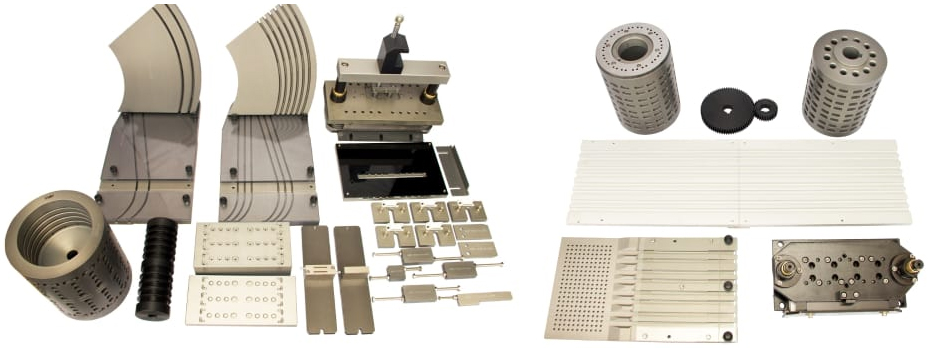

Rotary Tableting Machine Spare Part

Models:

8stn. / 10stn. / 12 stn.

12stn. Bolus Machine.

16stn. / 20 stn. – D Tooling Machine.

27stn. / 35stn. / 45stn. / 51stn. / 61 stn. Double Side Rotary Tablet Compression Machine.

All above machinery spare / change Parts

► Feed Frame.

► Worm.

► Fish Track.

► Lower Cam Track Filling.

► Lower Punch Ejection Cam Track.

► Die Lock Body.

► Tablet Scraper (Take Of Plate).

► Anti Turning Strip with SS Screw.

► Break Plug.

► Wedge (Ramp for Dozer).

► Pre – Compression Roller.

► Main Compression Roller.

► Uppar Pin Roll Assembly.

► Hydraulic Pump Handle with Pump.

► Powder Scraper (Teflon) etc.

SS Pallet

SS Pallet

Innovative Features :

► SS 304 / 316 grade stainless steel construction

► Manufactured, using heavy duty stainless steel

► High polish / matte finish

► Range of sizes, special sizes on request

► Range of styles, special styles on request

► Non-marking plastic feet (can be supplied without feet, as an option)

► Fully welded construction

► Appropriate for spray washing

► Suitable for loads up to 1000kg

► Ideal for use, in GMP environment

► Economical (stainless steel pallets have a longer life than aluminium / plastic)

Die Punch Cabinet

Material Grade

SS 304, SS316: B-Type, 50 Sets, 21 Drawers (Finish: Mirror / Matt Finish. Details: 21 Drawers – 50 Sets – B Tooling, Each Drawer: 50 Upper & 50 Lower Punch + 50 Dies. Total: 2100 Punch & 1050 Dies. 4 Bearings provided for smooth sliding, Lock, Nylon Bush to legs.)

Tablet Tooling Die Punch

The categories we make tooling’s for is undefined as we are equipped to manufacture any customized tooling required by the client to cater their needs, but here are a few commonly made tooling types :

► EURO STANDARD TOOLING

► TSM STANDARD TOOLING

► FETTE TOOLING including SEGMENT DIES

► KILIAN TOOLING

► JAPANESE STANDARD TOOLING

► BOLUS TYPE TOOLS

► MULTI TIP TYPE TOOLING CUP TYPE

► MULTI TIP TYPE TOOLING MONO BLOCK TYPE

► MICRO TIP TYPE TOOLS

► SNAP TAB TYPE TOOLS

► 3D TIP TYPE TOOLS

Our Other Sieves (products)

► Avialable In SS 316 & SS304 Quality,

► Perforation Size Ranging From 0.2mm Dia To 25mm Dia.

► Available In Size ranging From 100mm Dia To 400mm Dia.

► Crevice Free Gmp Design

► Super Right Finish

► Available In Size Ranging From 30mm Dia To 1220mm Dia

► Wire Mesh Size Available From 2# To 600# As Per

► International Standards

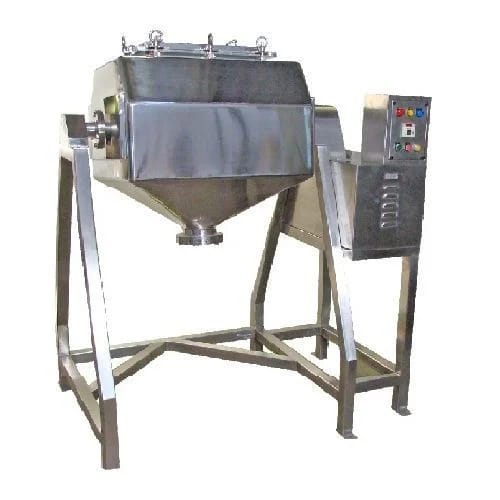

INDUSTRIAL BLENDERS

ANKITA ENGINEERING is a leading manufacturer and exporter of Industrial Blenders, offering high-efficiency mixing solutions for the pharmaceutical, food, chemical, and cosmetic industries.

Octagonal Blender Specifications

Capacity: 50L to 5000L

Blending Speed: 5–25 RPM (Variable)

Material: SS 304/SS 316 (GMP-Compliant)

Discharge System: Butterfly Valve

Automation: Optional PLC-based control or Manual Operation Control

Cleaning System: CIP/WIP (Clean-in-Place/Wash-in-Place)

Power Supply: 220V-240V/380V-415V, 50/60Hz

Safety Features: Interlocking system & Emergency stop, Explosion-proof design (optional)

Customization: Available as per production requirements

Rapid Mixer Granulator Specifications

ANKITA ENGINEERING is a leading manufacturer and exporter of Lab Model / R&D Equipment, designed to support research, development, and small-batch production in the chemical industries.

Interchangeable Bowl Capacity: 5L- 25L (Customizable)

Impeller Speed: 15 – 400 RPM (Variable)

Chopper Speed: 300 – 3000 RPM (Variable)

Material: SS 304/SS 316 (GMP-Compliant)

Control System: PLC-based automation with HMI touchscreen Manual Operation Control

Discharge System: Pneumatic / Manual

Safety Features: Emergency stop, interlocking system, overload protection Explosion-proof design (optional)

Cleaning System: CIP/WIP (Clean-in-Place/Wash-in-Place)

Power Supply: 220V-240V/380V-415V, 50/60Hz

Customization: Available for specific research and development needs

GRANULATION EQUIPMENTS

ANKITA ENGINEERING is a leading manufacturer and exporter of granulation equipment, providing high-performance solutions for pharmaceutical, food, and chemical industries.

Fluid Bed Dryer Specifications

Capacity: 30Kg to 500Kg per batch

Airflow Rate: 200–3000 m³/hr

Temperature Range: Up to 110°C

Material: SS 304/SS 316 (GMP-Compliant)

Heating Options: Electric Heater or Steam Coil for Hot Air Circulation

Automation: PLC-based HMI touchscreen control or Manual Operation Control

Power Supply: 220V-240V/380V-415V/ 50/60Hz

Safety Features: Interlocking system & Emergency stop, Explosion-proof design (optional)

Customization: Available as per production requirements

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam.